Sustainable Denim: Everything You Wanted to Know (But Were Afraid to Ask)

Sustainability is fashion's hottest buzzword. Here’s how to know if those jeans are actually eco-friendly—or just cleverly marketed.

If you’ve shopped for a new pair of jeans lately, you might have noticed a trend: From fast fashion to luxury designers, “sustainable denim” is an option just about everywhere. When you search the phrase, dozens of brands pop up flaunting all sorts of key terms in the product descriptions to promote their supposed eco-friendly styles—recycled, organic, upcycled, Fairtrade, deadstock, Tencel, inclusive, Made in U.S.A., vintage, clean.

Sounds great, right? On the surface, this seems like a positive development, but when you look a little closer, there’s a pretty big catch. The buzzword “sustainable,” when used to describe a specific piece of clothing, doesn’t really mean anything. There’s no standardized definition or guideline for what makes a garment sustainable. Any brand can use the term to market clothing as good for the environment when, in reality, it's most likely not all that much better than an item without that descriptor.

When it comes to denim, this sort of greenwashing—a deceptive marketing tactic, in which a brand makes false or overblown claims about its positive environmental impact—is a huge problem. Over the last decade, denim production has grown considerably. Each year, 4.5 billion pairs of jeans are sold around the world with sales in the United States reaching $15.1 billion in 2021. Though there is no exact number on the amount of denim that is discarded, consider that Americans consumers throw away an average of 17 million tons of textile waste per year. Especially taking into account the anecdotal evidence showing denim- and T-shirt-packed landfills around the world.

Worse, the process of making a pair of jeans is more involved than most other apparel. Denim creation requires two steps: fabric production and laundering or finishing. Both steps require energy, water, carbon emissions, and labor to complete. Even the most conscious denim company is likely still participating in something harmful because of the nature of the process.

As our interest in sustainable denim increases (searches rose 153 percent between 2020 and 2022, according to online search engine Lyst), so does confusion around it. Marketers use green labels or buzzwords without needing to back up their claims. For consumers, this makes shopping smarter incredibly difficult. Without proper knowledge of what makes denim so bad for the planet, it's almost impossible to decipher which brands are taking advantage of eco popularity and which are actually trying to make a difference. To help you understand the complicated world of sustainable denim, we looked at five key areas—material, process, labor, marketing, and end of life—and spotlighted changes to each step that must be made for denim to be truly good for the planet.

What is denim made from?

Though some brands add a small amount of spandex or elastic to jeans to give them stretch, denim is made primarily from cotton. “All cotton requires a lot of water to grow,” says Preethi Gopinath, associate professor of textiles at Parsons. “The farming of cotton is a drain on resources because of the amount of water it uses, the pesticides required for larger yields, and the fertilizer. All of these are polluting.”

Many brands have tried to make the switch to organic cotton, which is decidedly better for the environment, but there are some issues with this, as well. Generally, in order to claim a piece of clothing is made from organic cotton, the fiber needs to be spun from non-GMO seeds and grown without the use of pesticides. However, recent reporting in the New York Times found that many brands have circumvented these standards through certification fraud—making claims that the product is organic even when it may not be. This is despite a U.S. Department of Agriculture rule requiring that 95 percent of a product must be organic to use this designation.

Get exclusive access to fashion and beauty trends, hot-off-the-press celebrity news, and more.

If organic cotton were produced according to Global Organic Textile Standard (GOTS) standards, it would be a better option than conventional. “Non-organic cotton is generally grown in fields that have older or more outdated irrigation systems that don't necessarily utilize water in the best way, which can lead to over-watering and wasted water,” says Kevin Child, director of marketing at denim brand Edwin, which uses 50 percent GOTS-certified cotton, with plans to be fully GOTS-certified in the near future. He adds that, “the pesticides can run off into groundwater, into streams and nearby water sources that are used by the local communities, which makes it less safe to consume.”

There are, of course, other sustainable denim options beside newly farmed cotton. Upcycling, which means turning old fabric into a new piece, is gaining popularity, especially among smaller designers. Some brands, like Levi’s, partner with upcycling companies such as Re/Done to create brand-new styles out of their old materials. Other independent designers like EB Denim and E.L.V. (East London Vintage Denim), have crafted their entire brand out of only thrown-away denim.

How does cotton become a pair of jeans?

Even though denim comes in different colors, when we think about a classic pair of jeans, they’re blue—like the cover of ‘Born in the USA.’ That’s because, historically, indigo was used to color denim. Unlike other natural dyes, indigo sticks to the surface of cotton instead of seeping into the fiber, and when it’s washed, some of the dye releases, creating those gorgeous fades we’ve come to love. Real indigo is a natural resource, though, so most brands use a synthetic dye to create the same effect. Depending on how the factories use that manufactured dye, it can be detrimental to the environment.

Synthetic indigo most commonly comes in powder form. To make that powder dissolve in water before dying the fabric, reduction agents like sodium dithionite or hydrosulfite are often added. When the finished jeans are washed, these harmful-to-sea-life chemicals rinse off into waterways. A truly sustainable dying process instead uses lasers to make the indigo soluble, lessening the amount of dye that goes into the water supply by 100 percent. This is because electricity goes directly into the dye bath and doesn't use additional chemicals.

Once the cotton is dyed, it’s then woven into fabric to be cut and sewn into pants, overalls, a jacket, shorts, a skirt, perhaps even a corset (denim is very trendy lately). This results in a lot of waste—everything that’s leftover after the item is cut out of the pattern. Some factories work with recycling companies like Stelapop, a facility that turns textile waste into furniture, but others—even the ones using lasers and organic cotton—are still putting leftovers in the garbage.

What makes denim different—and even more harmful to the planet—than clothing made from other fabrics, is the step that comes next: In order to get the “washes” customers are looking for, most manufacturers literally wash them. This process can waste up to 80 liters of water per pair. And if the facility isn’t recycling their water, the chemicals and dyes enter waterways.

To create details like whiskers and fading manufacturers traditionally use pumice stone or sandpaper. The sand then goes into the water causing a sludge that blocks irrigation systems. The stones are also inexact, causing damage to jeans, in turn creating even more waste. The alternative: Use lasers to create the designs in the finishing process, thereby saving both the extra wash and the pumice.

“Laser is cleaner than traditional hand sanding because it eliminates the lint that comes from scraping,” says Kathy Kweon, president of Saitex, a denim manufacturer based in Vietnam and Los Angeles.

At their facility, which makes jeans for several brands including Madewell, Saitex uses an advanced laser-burning system to create the exact same washed look that dyes and sandpaper do. “Traditionally, you would do the cutting and you would do the sewing and then it gets into the laundry, then through the hand sanding, and then through another wash. There's a lot of process going back and forth,” says Kweon. Using a laser for all of this eliminates the need for water completely.

Who is making our jeans?

When we think about sustainability, we often think about textiles and the impact they have on the planet. But in order for a brand to be truly sustainable, it needs to protect its workers, too, from cotton growth to cut and sew. Unfortunately, this is generally not the case.

On the farming side, 37 percent of cotton is sourced from India and, according to Better Cotton, a sustainability initiative that aims to make the production of cotton safer for workers, “Many cotton workers face poor working conditions, discrimination, and low wages, particularly those from underprivileged, rural communities, or migrant families. Children, too, may be vulnerable to working in the cotton fields.” Without proper tracing of the entire supply chain—a rarity for many brands—it’s impossible to know whether or not the farmers were treated properly.

Some brands are also profiting from farmers who have made the responsible (and costly) switch to organic farming by not upping their payment even though organic cotton has a lower yield. “Prices are often controlled and there are price caps for cotton output,” Gopinath says. “Regardless of how small the crop is, the farmer gets the same price.”

In China, where 20 percent of the world supply of cotton comes from, the risk of issues in the supply chain is even more apparent. There, about 85 percent of cotton is made in Xinjiang. The United States has condemed the Chinese government for it’s treatment of people in the area, including the forced labor of the Uyghur Muslim people and genocide in the region. "Right now, there is near certainty that any brand sourcing apparel, textiles, yarn, or cotton from the Uyghur Region is profiting from human rights violations, including forced labor, both in the Uyghur Region and more broadly throughout China,” the Coalition to End Forced Labor in the Uyghur Region told the BBC in May 2021.

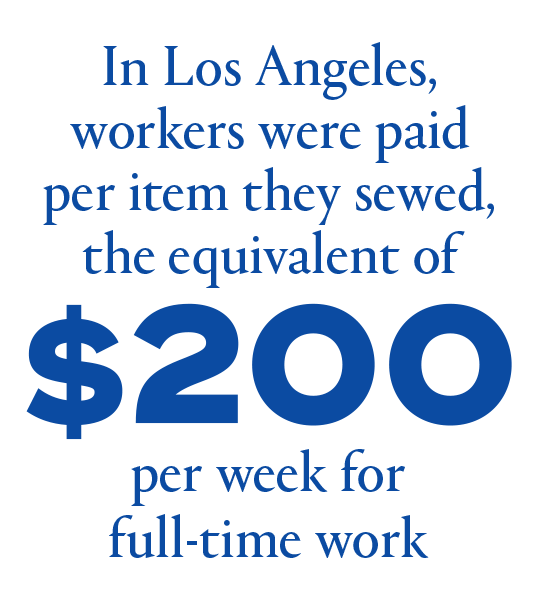

In the factories, where that cotton is made into denim, wage theft, mistreatment, and abuse is rampant. In some Los Angeles facilities, for example, workers were paid per item sewed, the New York Times reported—the equivalent of about $200 per week for full-time work. Many of these workers were making denim and other products for major brands like FashionNova.

What happens to jeans when we’re done with them?

Even when all of the above steps are conducted with sustainability in mind, if there is no plan for what happens to the jeans when a person is done wearing them, then they aren’t sustainable. Waste is a major issue in the fashion industry, with unwanted clothing from the United States and Europe being shipped around the world often because of trade deals with places like Ghana and Chile. There, clothing piles up in landfills, and as they break down, the chemicals and dyes enter groundwater, making it toxic for people and animals.

Some brands, like Edwin USA, Levi’s, and Madewell, have implemented buyback programs in which they ask customers to sell back jeans for a percentage off of or dollar amount toward their next purchase. “The buttons and rivets are saved for other uses. And the denim itself is shredded down and mixed with a natural enzyme polymer, essentially a more natural form of glue binder,” Child explains about Edwin USA’s program. “They form these sheets almost like plywood boards, and they are used in glue of wood for a multitude of different uses, from furniture to accessories—home accessories, fashion accessories. They're experimenting with different uses now, such as possibly making toothbrush handles.”

What does greenwashing have to do with truly sustainable denim?

We’re at a point in fashion where waste, water usage, labor abuse, and toxic chemical use have gotten so bad that sustainability should be core to every single brand making new clothing—no matter what. Unfortunately, many brands have taken the consumer desire for change as a way to sell more stuff, without actually doing the work to create a truly sustainable product.

If a brand is selling organic cotton jeans, but they are using excess water to launder them, not making a plan for their waste materials, or paying their workers inadequately, then it is not a sustainable brand. If a company is creating upcycled denim in one factory but not paying workers a living wage in another, then they are not sustainable. It seems harsh, especially when pivoting production is a huge undertaking, but it's a line customers have to draw. Marketing themselves as sustainable has gotten too easy for fast-fashion brands, and that takes away from the designers who are doing it right.

It’s not on consumers to fix all of the problems the fashion industry has created, but arming ourselves with knowledge about the products we buy is a powerful tool. When you’re looking for sustainable denim, yes, look for organic cotton or recycled materials. Check to see if the company is using laser technology to reduce the amount of water needed—most will actually state this on their website. There should be full transparency about where the materials are farmed and crafted, and what wage workers are making. There should be a way for customers to give the products a second life instead of throwing jeans in the trash. And importantly, we the customers should be treated like we are a knowledgeable part of the fashion ecosystem, not fools to be tricked into buying something that looks good but does bad.

Alyssa Hardy is a journalist and author based in New York City. She was formerly senior news editor at InStyle and fashion news editor at Teen Vogue. She is the publisher of “This Stuff,” a weekly fashion newsletter. Her work has been featured in Vogue, NYLON, Refinery29, Fashionista, and elsewhere. Her book Worn Out: How Our Clothes Cover Up Fashion’s Sins comes out in September 2022.