Small Business Spotlight: Neems Jeans

"Starting a denim company like Neems Jeans meant I could impact people's lives, the environment, and women's relationships with their bodies."

Women running their own companies? We love to see it. In our series Small Business Spotlight, we chat with independent fashion entrepreneurs about their journey to be-your-own-boss status. Here, tips for raising funds, developing a marketing strategy, navigating social media, and more—straight from women who have done it themselves.

Despite Daniela Rodriguez's longtime struggle to find jeans that fit her properly, the then-Deloitte consultant took yet another trip to the mall in the fall of 2019, hoping to find a flattering pair. Again, an unsuccessful trip left her disappointed, defeated, and self-conscious. But she was also motivated. Curious about other women's experiences trying on denim, Rodriguez returned to the mall the next day to speak with other women searching for jeans. Unsurprisingly, most women she talked to avoided jean shopping as much as possible. Rodriguez was determined to find a solution and, in 2020, left her career at Deloitte. Jumping off her string of bad experiences and using the valuable insights of other women struggling to find denim, Rodriguez took her life savings and launched the concept for Neems Jeans, a premium, custom denim brand ethically made in LA.

Ahead, we spoke with the small business owner about jumping on her lightbulb moment, her made-to-measure business model, and how she gives back to her local community.

On Finding Your Calling:

Little by little, I started researching the denim industry and realized that not only is the sector very size exclusive, but jeans are made for a specific body type that few people have. Not only that, but the environmental impact [of the denim industry] is insane, from the toxic dyes and the number of jeans that go into landfills or are incinerated to the release of greenhouse gases and the poor working conditions of employees. It's just a problematic industry. That moment, [speaking with women trying on jeans] in the mall, was a lightbulb moment for me. Starting a denim company like Neems Jeans meant I could impact people's lives, the environment, and women's relationships with their bodies.

On Sourcing Fabric:

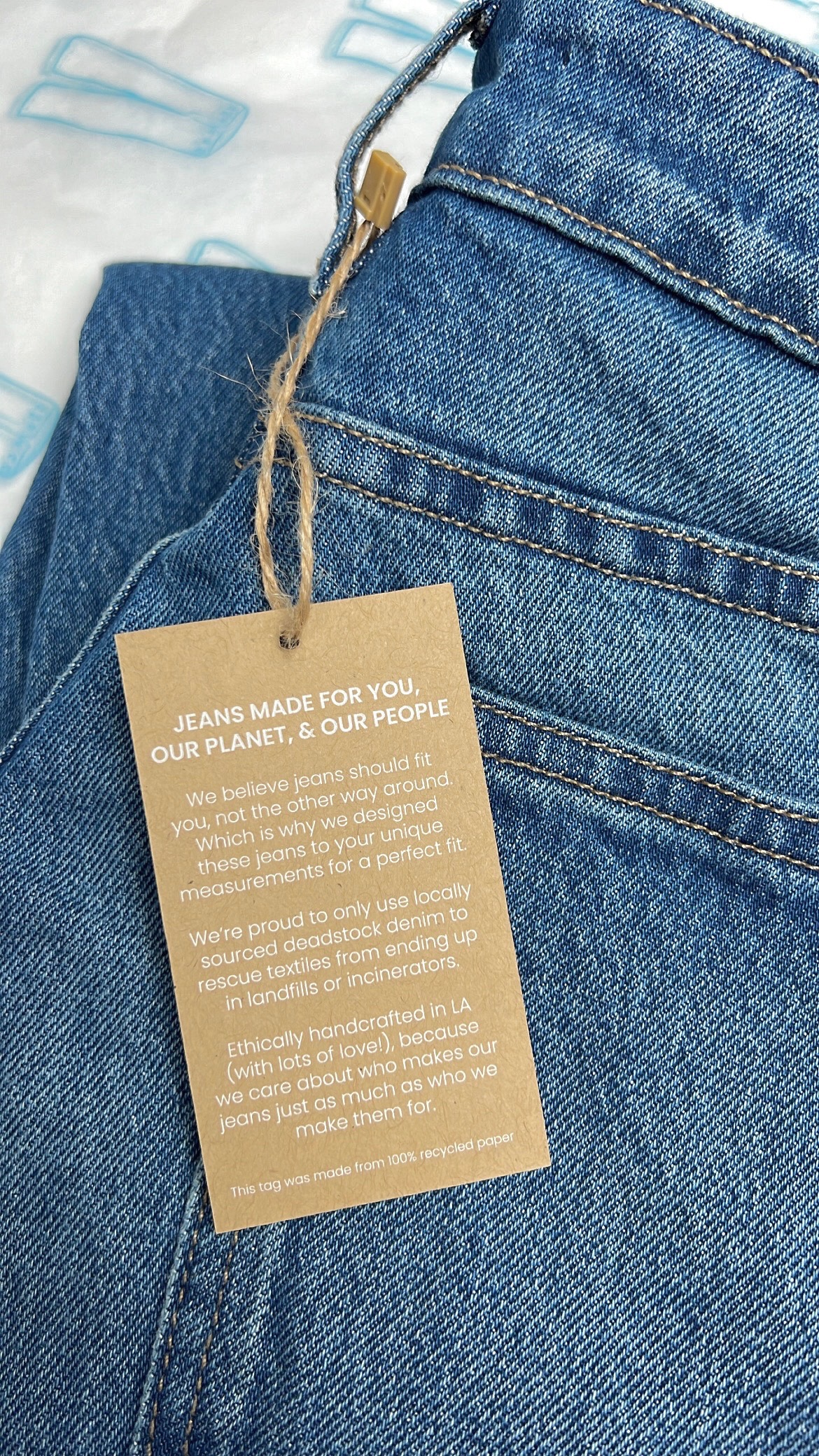

Each pair of our jeans is made exclusively of deadstock denim. I source all of our fabric here in Los Angeles from Pacific Blue Denim. This wholesaler rescues deadstock denim that large mills no longer need and is typically thrown into landfills or incinerated. It's perfectly good denim; it's just no longer required for [the original company's] production, and by using it ourselves, we divert the textile waste.

I have very high standards with the fabrics I source and am very intentional about ensuring that the denim mills I work with have proof of necessary certifications within the industry.

On Customization:

The nature of the made-to-order business model [especially in denim] lends itself to sustainability. We don't mass-produce garments and instead begin manufacturing once we receive the order; this drastically helps reduce the amount of textile waste that goes into landfills or incinerators.

Get exclusive access to fashion and beauty trends, hot-off-the-press celebrity news, and more.

Our customer has two options to measure themselves: manualy with free measuring tapes, or with our mobile body scanners. The mobile body scanner has been super successful because people aren't confident measuring themselves correctly. After they measure, customers can customize their jeans on our website, choosing whatever style and wash they want. From there, I digitally design their jeans on our unique software.

On Producing Locally:

We rent a space in a factory in Vernon, California, where I laser-cut the jeans and hand them off to one of our sewers. From there, it goes into the washhouse. After the washhouse, I add the finishings, like buttons and tags, package them up and send them out. We've streamlined the process, so the turnaround time is about two weeks. I always wanted to ensure we perfected localized production so that I could oversee every single part of the supply chain. So I can guarantee that our employees have excellent working conditions and are paid above minimum wage here in California.

I've gotten to know our worker's stories very intimately. All of them have left their families to come to the United States. They send money back home to support their families. We do the same with our family in Venezuela. Overseeing production, and supporting members of my Latino community, has always been an essential part of the business model.

On Using Her Platform:

Using my social media presence for education has been crucial to Neems Jeans. I'm always trying to educate people on facets of the fashion and denim industry, from size-exclusivity to deadstock denim, to recognizing vanity sizing. I always get messages from customers saying they've changed things to make them more sustainable because we have been talking about it.

Rachael is a sustainability-focused fashion writer and creator. She works full-time as the Brand and PR coordinator for Mara Hoffman whilst focusing her writing efforts on covering sustainable fashion for Marie Claire and EcoCult. As an Aussie living in Brooklyn, you'll catch her splitting her time between Sydney & NYC.